Battery Monitoring System (BMS)

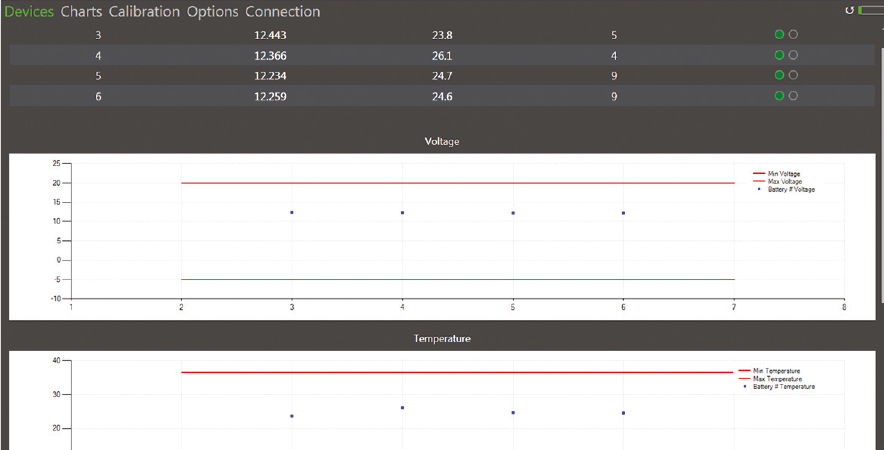

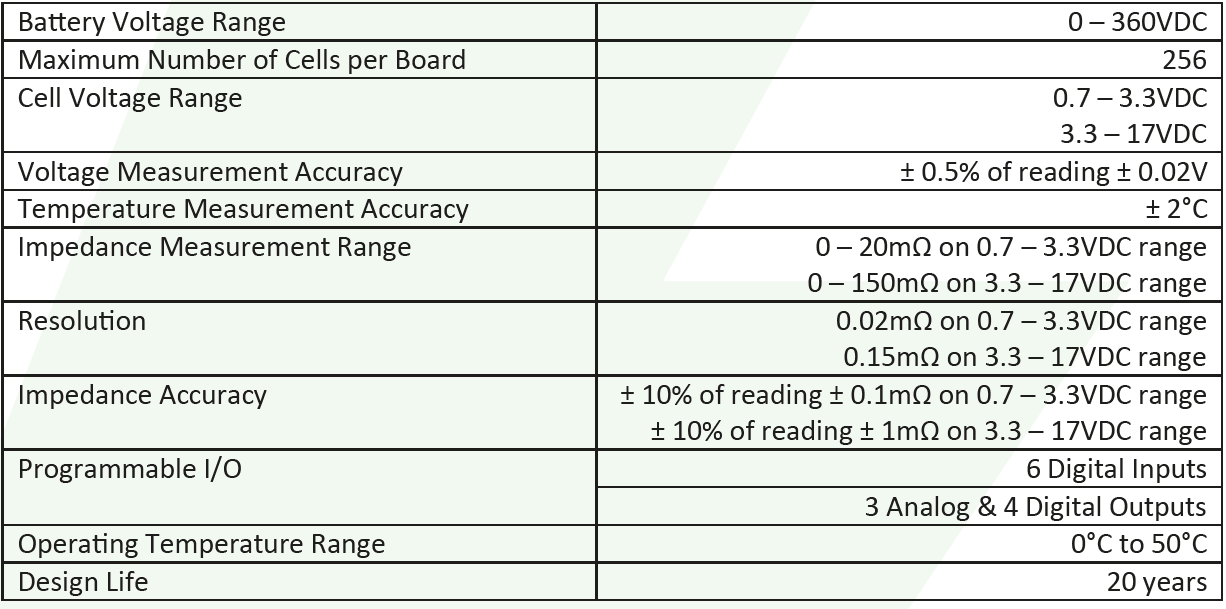

An Uninterruptible Power Supply (UPS) is only ever as good as its battery bank, and there any many ways batteries can be rendered ineffective. Age, temperature, and incorrect charging can slash cell capacity. Terminals can work loose over time causing high resistance. Operator error or spurious trips can leave your battery isolated without you even knowing about it. Our Battery Monitoring System (BMS) is the safety net your batteries need. The condition of each cell and the string as a whole is logged, highlighting any issues as soon as they develop, so they can be rectified before they cost you money.