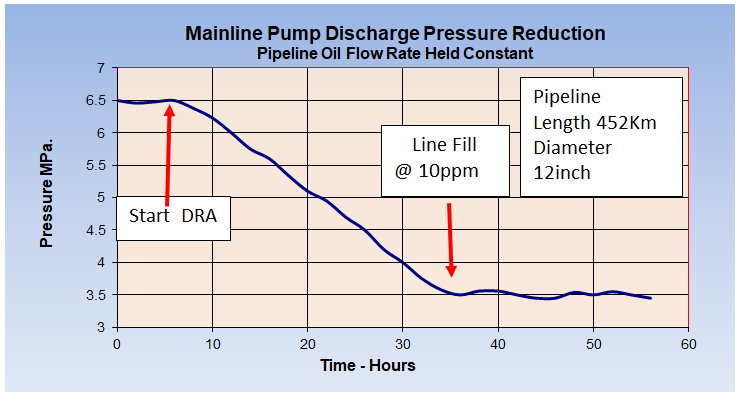

Thousands of kilometres of crude oil pipelines around the world depend on drag reduction agents (DRAs) to increase pipeline capacity, improve transport efficiency, and achieve savings in pumping power.

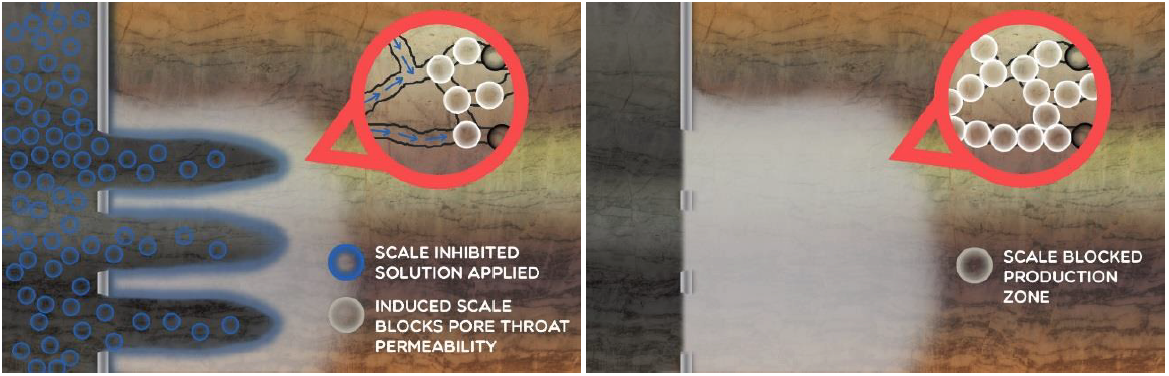

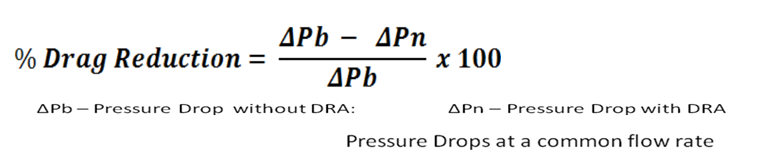

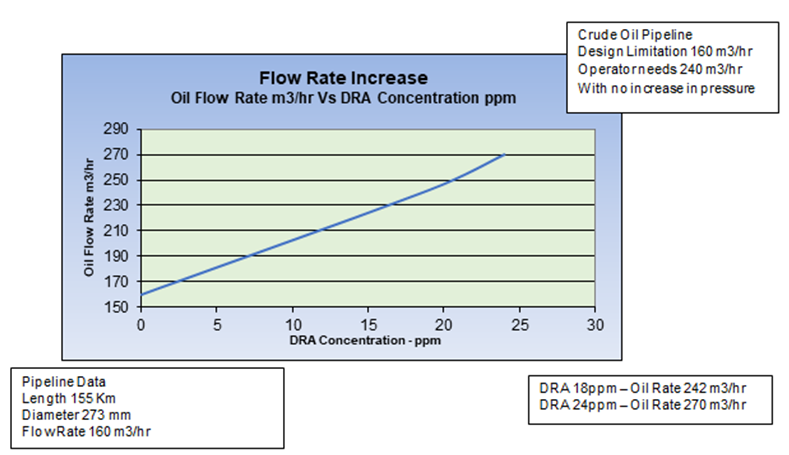

Drag Reducing Agents (or Additives) are chemicals that when injected into a pipeline, where the fluid is in turbulent flow, reduces the frictional pressure drop along the pipeline. The drag reduction in pipe flow means the whole pipeline can be operated under lower pressure, making the whole pipe system safer.

DRA’s are slurry products with an active high / ultra-high-molecular-weight polyalphaolefin dispersed in a carrier. Carrier Selection can be application specific, or customer preference.